Our expertise

FAT & e-FAT expertise

The FAT (Factory Acceptance Test) is a crucial step in our production process. This entails a series of tests and verifications carried out on our equipment before it is delivered.

Our skills

Factory FAT with our customers

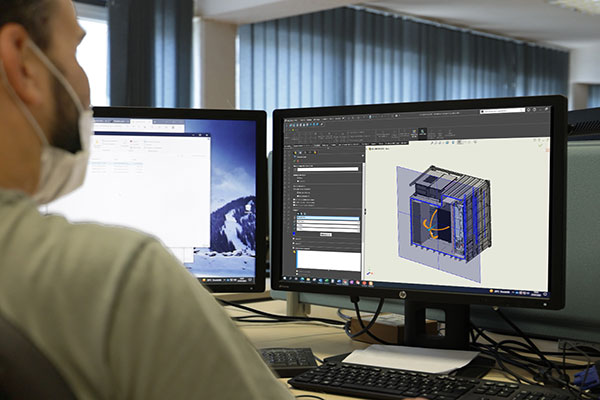

e-FAT via digital tools

Customer monitoring and support service

providing you with support

A quality approach

Aventech relies on its monitoring services to:

- Conduct intermediate and final trials on the production islands

- Monitor our standard test procedures with a control report given to the customer

- Conduct the FAT in the workshop, in the presence of the customer

We can thus demonstrate the reliability, compliance and safety of our equipment while ensuring that it is compatible with the customer’s technical recommendations

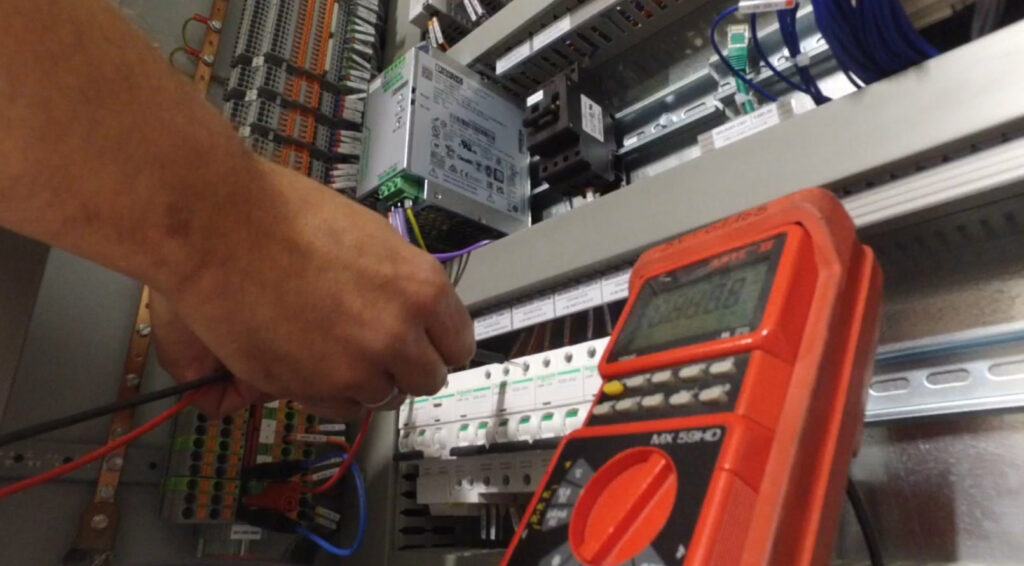

- Supply of drawing files

- Tightening torque inspection

- Wire-by-wire inspection

- Insulation inspection

- Ground continuity test

- Dielectric inspection

- Functional tests for customer support (powering up and programme injection on automaton)

In addition to the FAT on site, we offer the e-FAT (Electronic Acceptance Test).

e-FAT is recognised for its practical and ecological side: Financial savings concerning your teams’ travel, saves time, reduces travel and therefore the carbon footprint.

- Remote test via high-resolution video

- Practical and ecological benefits

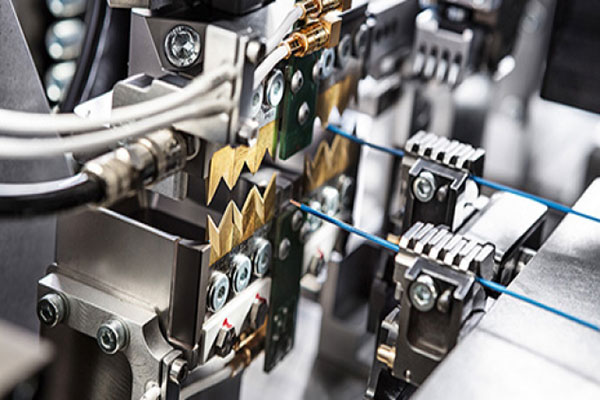

We develop test benches that are specific to customer equipment for autonomous tests during mass production, as such strengthening our commitment regarding the reliability of your equipment.

We also make a test room available with temperature and humidity control for extended tests.