Our solutions

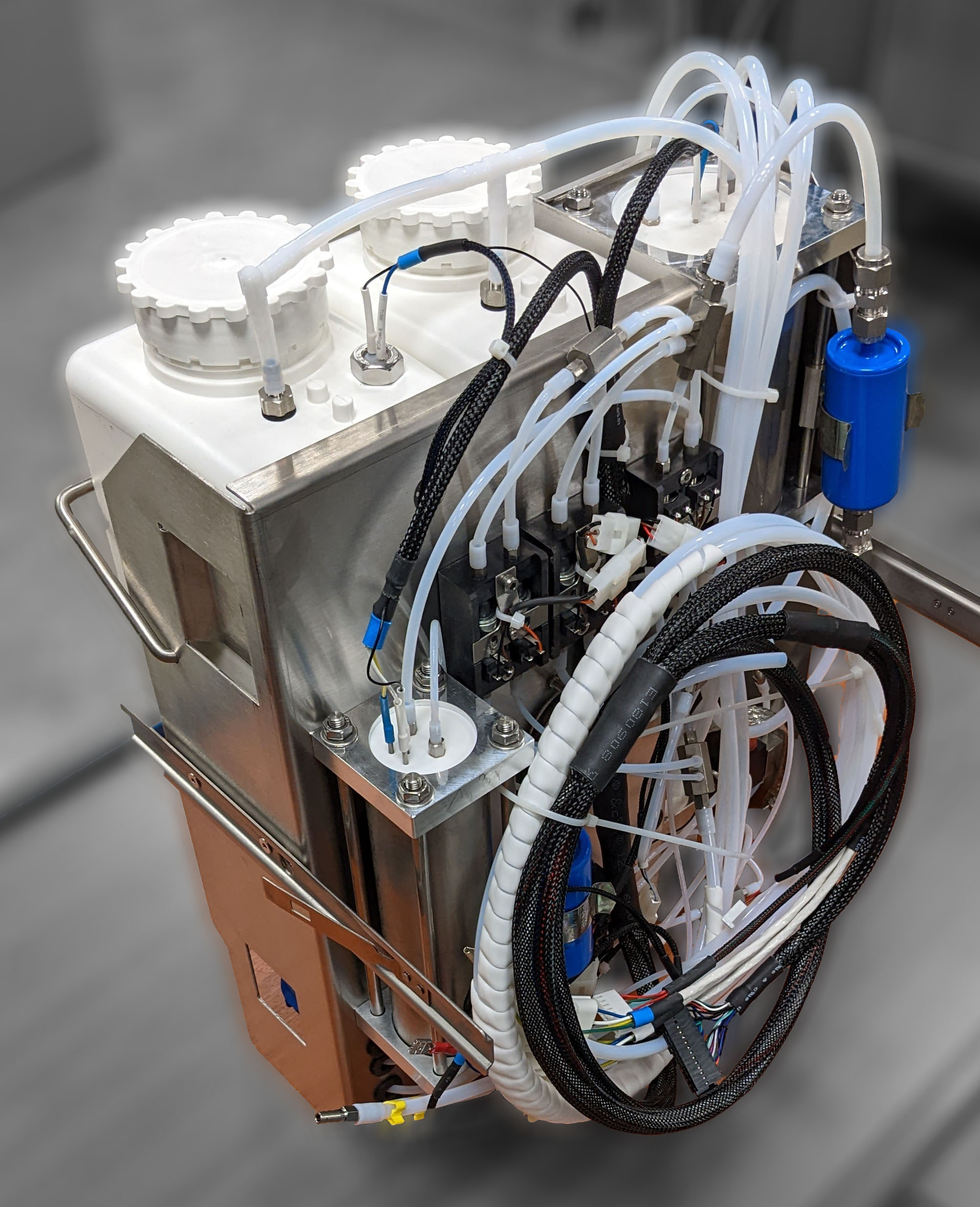

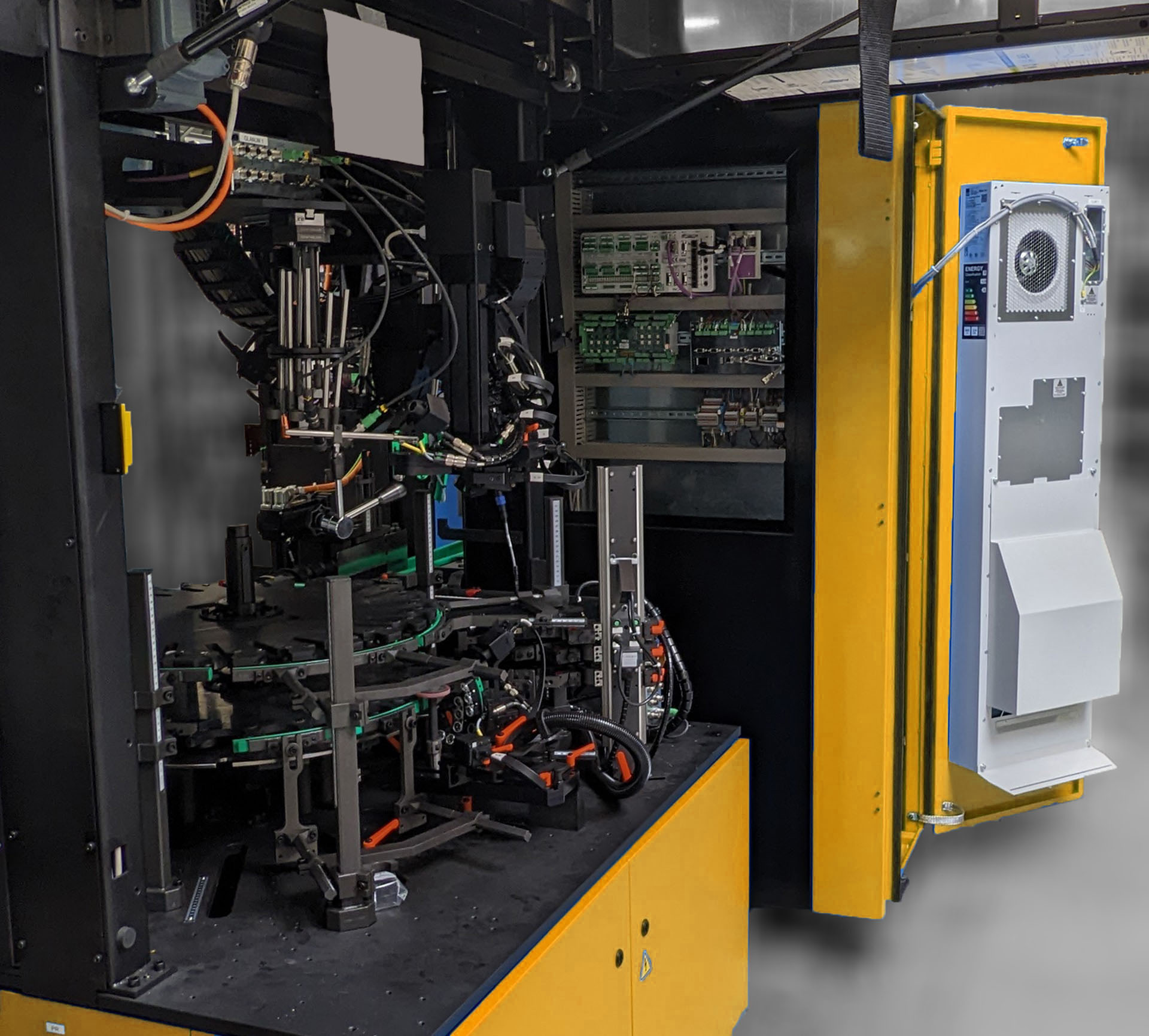

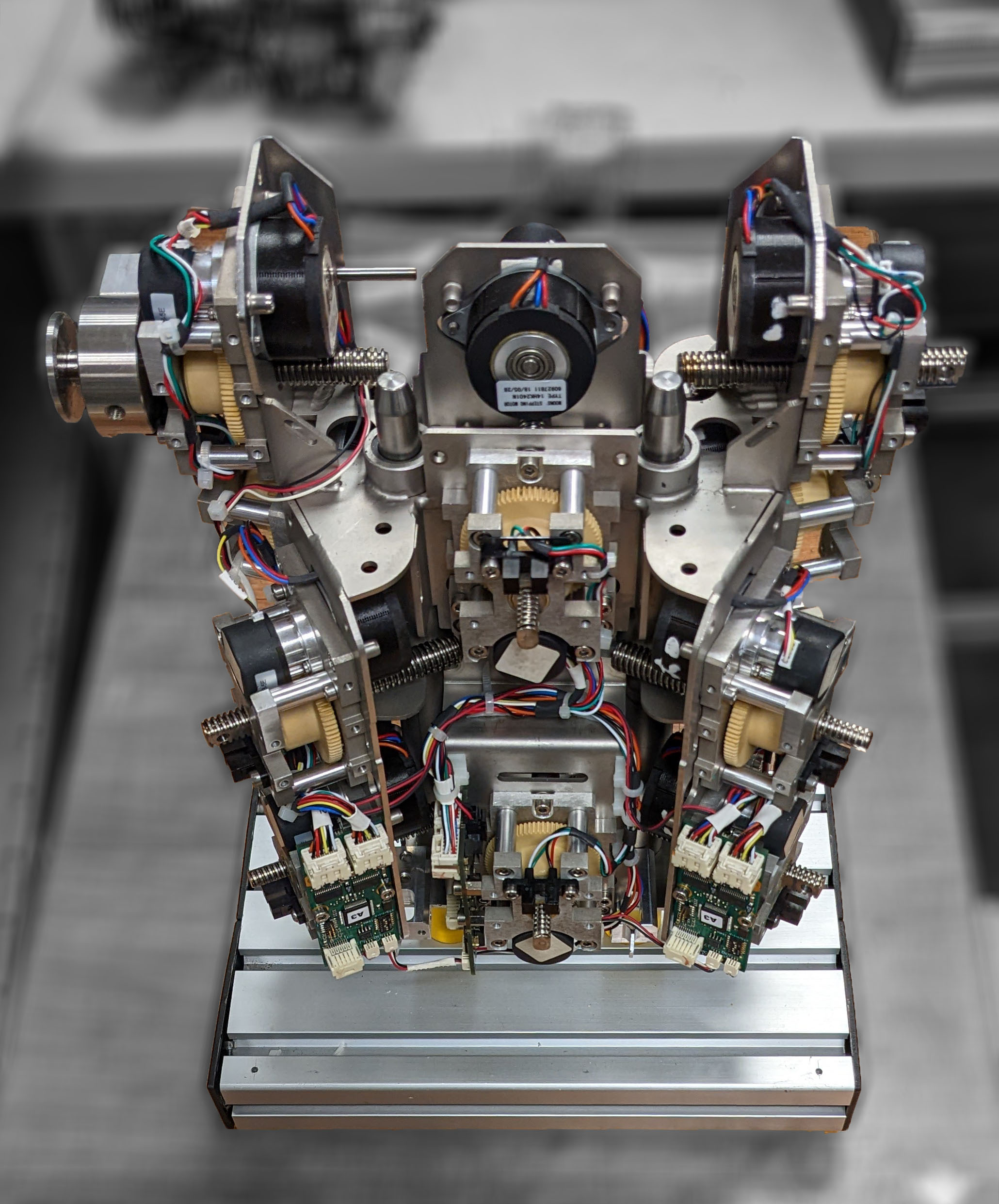

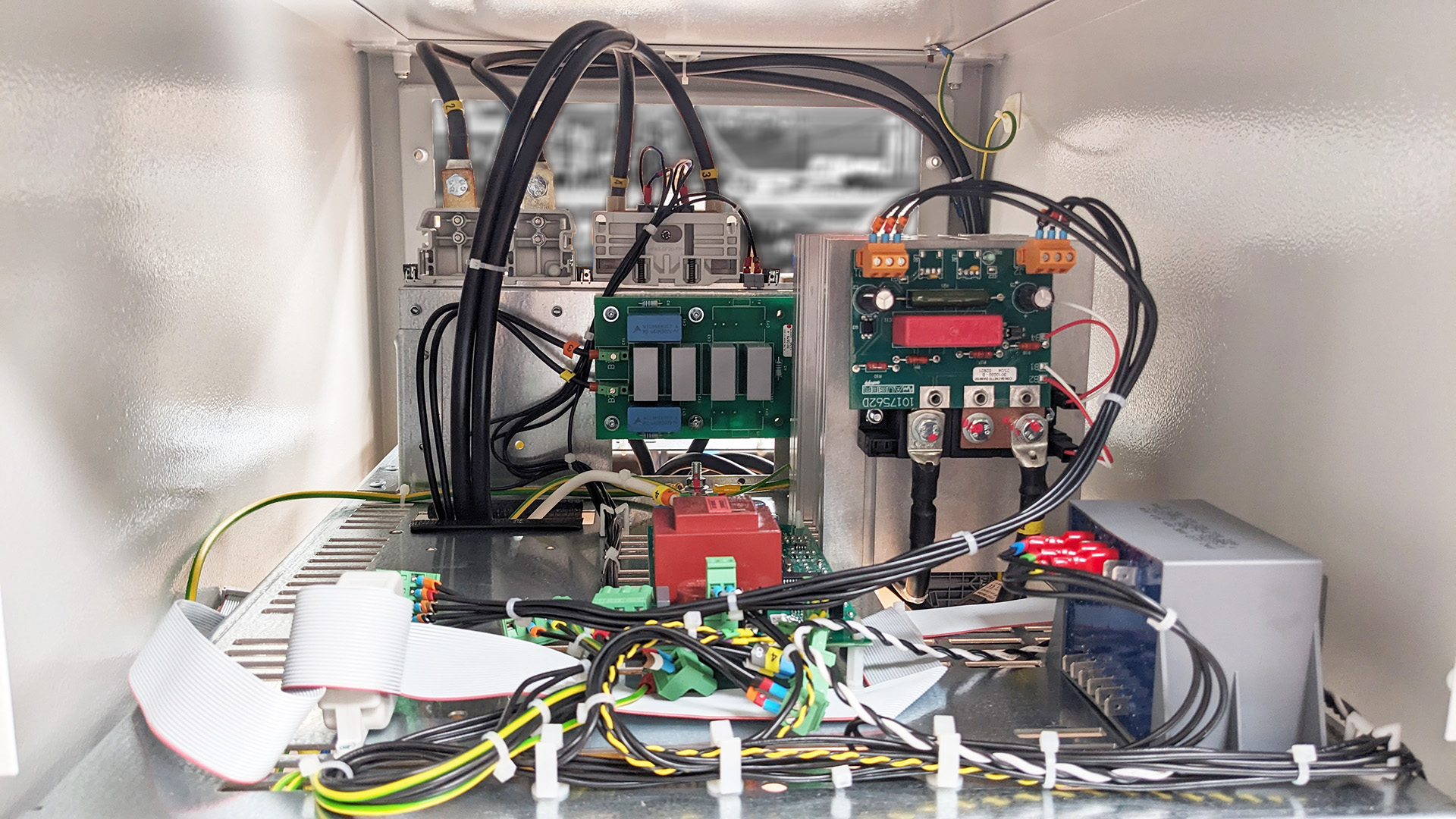

Electromechanical integration

A 1st-rate stakeholder in industrial subcontracting at the service of our customers, we offer customised support for your project, whether occasional or cyclical.

expertise

Our know-how

Our added value entails adapting to our customers’ expectations by making the suitable resources available:

-

Human resources Technical studies, sourcing, methods/industrialisation, Supply Chain management, management of quality, dedicated production teams, etc.

-

Material resources Production areas, dedicated industrial processes, technology island, financial resources, etc.

We meet your key criteria

To satisfy your requirements, we implement a complete approach to quality management.

Our various departments monitor Customer, Internal and Supplier quality performance.

The way we manage the supply chain as well as our production process allows us to achieve high logistics efficiency (average OTD rate on industrialised repetitive markets of 99%).

We strive to provide solutions with high economic performance (process automation, efficient sourcing, use of our sites abroad, etc.).

For our customers, we undertake to actively participate in the search efforts for technical optimisation and productivity.

Project expertise

Our approach

Designing the solution

- Receiving and interpreting the Customer's need

- Electrical and mechanical study (if necessary)

- Defining the process and the Supply Chain

- Prototype Phase

Setting up the process

- Implementing the solution

- Industrialisation (range, operating procedure, full production chain)

- Pre-series

Mass Production

- Upstream and downstream flow management

- Assembly / wiring / adjustments / monitoring

- Packaging and delivery

Project expertise

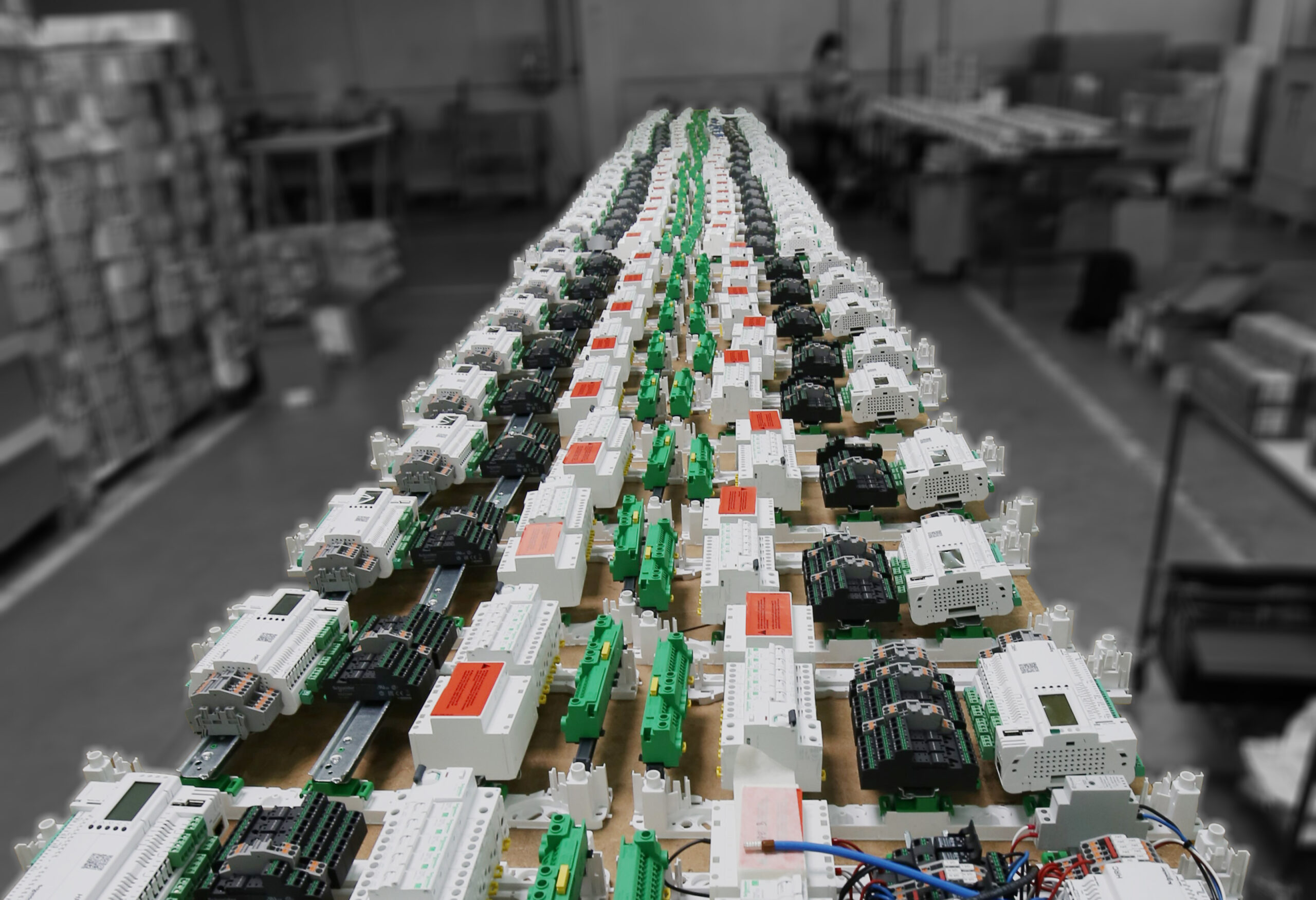

Electronic application

To lend support to its Customers towards a global and competitive offer, we expanded our services in 2016 by developing an electronic subcontracting activity.

Backed with its 2 production sites located in China (Wuhu) and Tunisia (Mornag), the service offered today is identical at both factories and includes:

- Industrialisation and technical support,

- Purchasing,

- Board assembly,

- Tests, calibrations…

- Varnishing, resinning, etc.

Our SMT lines are operated by qualified personnel and make it possible to assemble a wide range of SMD boxes from the 0201 format to µQFN. The visual inspections conducted on AOI machines supplemented by our training in the IPC A-610 standard help to obtain a highly compliant Product. We can also provide you with support in setting up function tests according to customer specifications.

As the electronic boards are then mounted into the equipment produced in our integration workshops, these tests guarantee proper operation in their final environment.

With our expanded offer, we provide our customers with a global solution with a single contact.

locations

International sites

-

Remote factory: 2,000 m² in Mornag, Tunisia

-

90 employees

-

Integration/Assembly of electromechanical sub-assemblies

-

Production of electronic boards (Board assembly, tests, calibrations, varnishing, resinning and mounting, etc.)

-

Wiring, Bundles, Plates

-

Weekly Flow (Tunisia/France)

-

Remote factory: 3,000 m² in Wuhu, China

-

40 employees

-

Production of electronic boards (Board assembly, tests, calibrations, varnishing, resinning and mounting, etc.)

-

Test, calibration and assembly of products

portfolio

Some of our achievements

- All

- Intégration électromécanique

- Intégration électronique