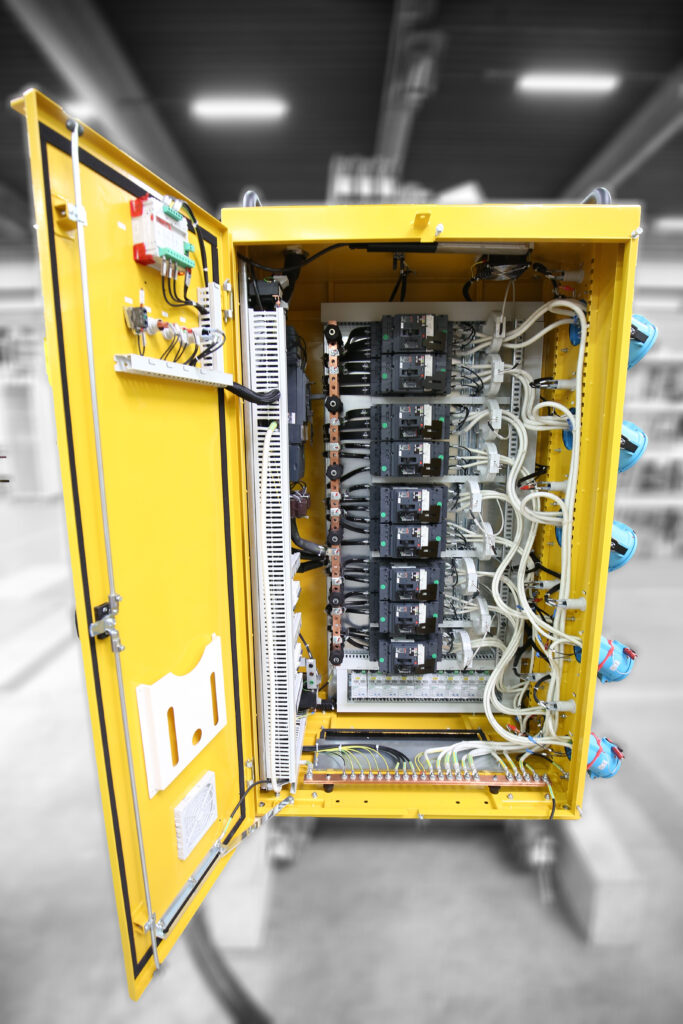

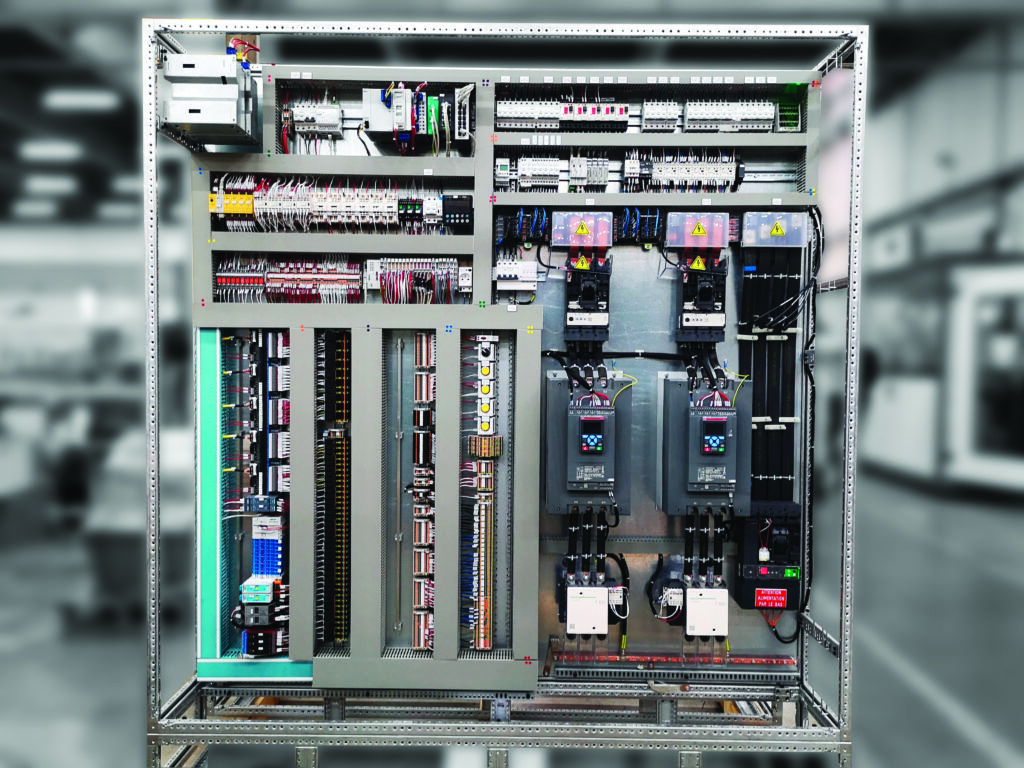

Electrical panels

Power distribution and conversion equipment

Aventech is a French industrial panel builder, recognised for more than 50 years for its expertise as a designer and manufacturer of distribution and monitoring and control panels for the energy sectors (nuclear, hydroelectricity, hydrogen, biogas, etc.), infrastructures (railroad, marine, mobility) and industries (special machines, industrial processes).

expertise

Our know-how

We work right from the customer’s technical definition phase by providing the skills of our electrotechnicians with customised support. Aventech is recognised for working in sectors with high technical constraints and in demanding conditions.

With support from our purchasing department, we have developed and consolidated a set of strategic suppliers that allow us to work in multi-brand mode and be proactive in suggesting solutions for our customers. Our company has a technology island comprised of several automated machines that makes it possible to automatically launch production for all or a part of the functions of an electrical panel.

-

Mechanical and electrical studies (sheet metal drawings, single-wire diagrams, interconnection diagrams, detailed nomenclature, ground and equipotentials, etc.)

-

Supplier price comparison and equipment selection

-

Assembly of standard and/or specific sheet metal casings

-

Industrial assembly and wiring of electrical components

-

Production of busbars (cutting, folding, punching, drilling and tapping)

-

Monitoring and Testing (wire by wire, dielectric, insulation measurement, power up, injections and functions to be studied according to customer need)

-

Creation of As-Built files

-

Factory Acceptance (FAT)

-

Packaging and Shipping

customisation

Customisable functions

Standard or customised made of steel, stainless steel, aluminium or polyester.

- Junction Box

- Box

- Plate

- Control console

- Standard cabinet

- Customised cabinet

- Single-piece or joinable cabinet

- Multibrand component assembly according to customer specifics

- Bus Ducts (tinning before or after forming, Epoxy treatment)

- Rated service voltage up to 690 Vac

- Rated insulation voltage 1,000 V

- Nominal current up to 6,300 A

- Short circuit holding current: 130 kA/1 s

- Up to 3,200 A according to IEC 61 439-2

- From 1 to 4b

- From 111 to 333

- Tightening torque inspection

- Dimensional and thickness check

- Dye-penetrant testing

- Development of test resources (test bench) to autonomously test equipment right off the line

- Management of associated AIPs and CTIs

- Awareness of the personnel as to nuclear safety

- Training of the personnel according to the criteria of IPC-A-620, class 3

- Training of our research personnel to the specifics of RCC-E

- Study, manufacture and inspection of equipment with IPS-K3 safety classification

portfolio

Some of our achievements

Standards

Applicable standards